This technology platform integrates the most recent advances in fluid and heat transmission, material safety, and advanced material research that offer customers a high-level vaping experience.

Similar to a CPU for a computer, VPU stands for Vaping Processing Unit.

VAPE EXPERIENCE

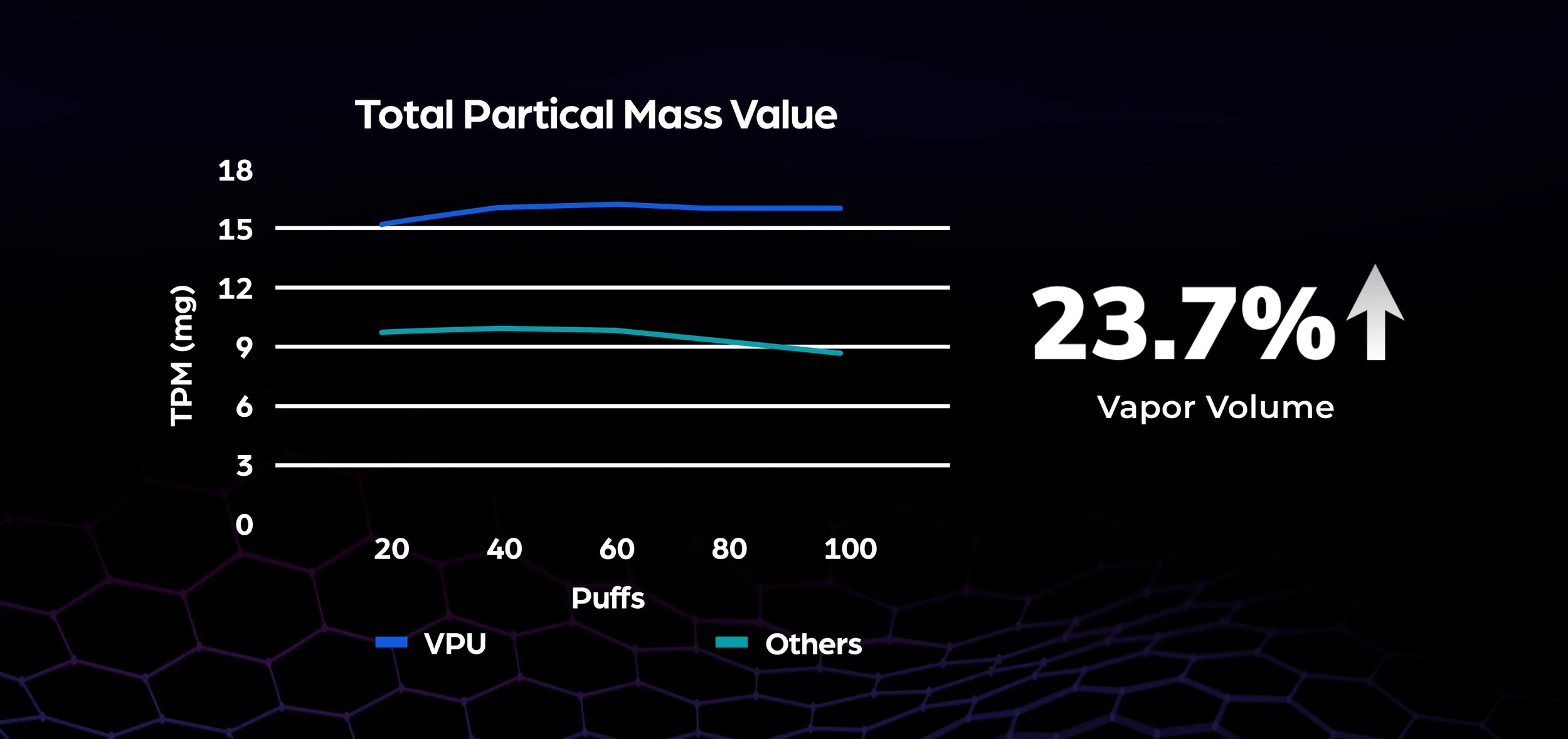

Heat Generators

Heat generators are one of the most important components of electro-atomization. By using VPU technology, the cloud volume increases by 23.7%, ensuring each puff delivers a consistent flavor profile.

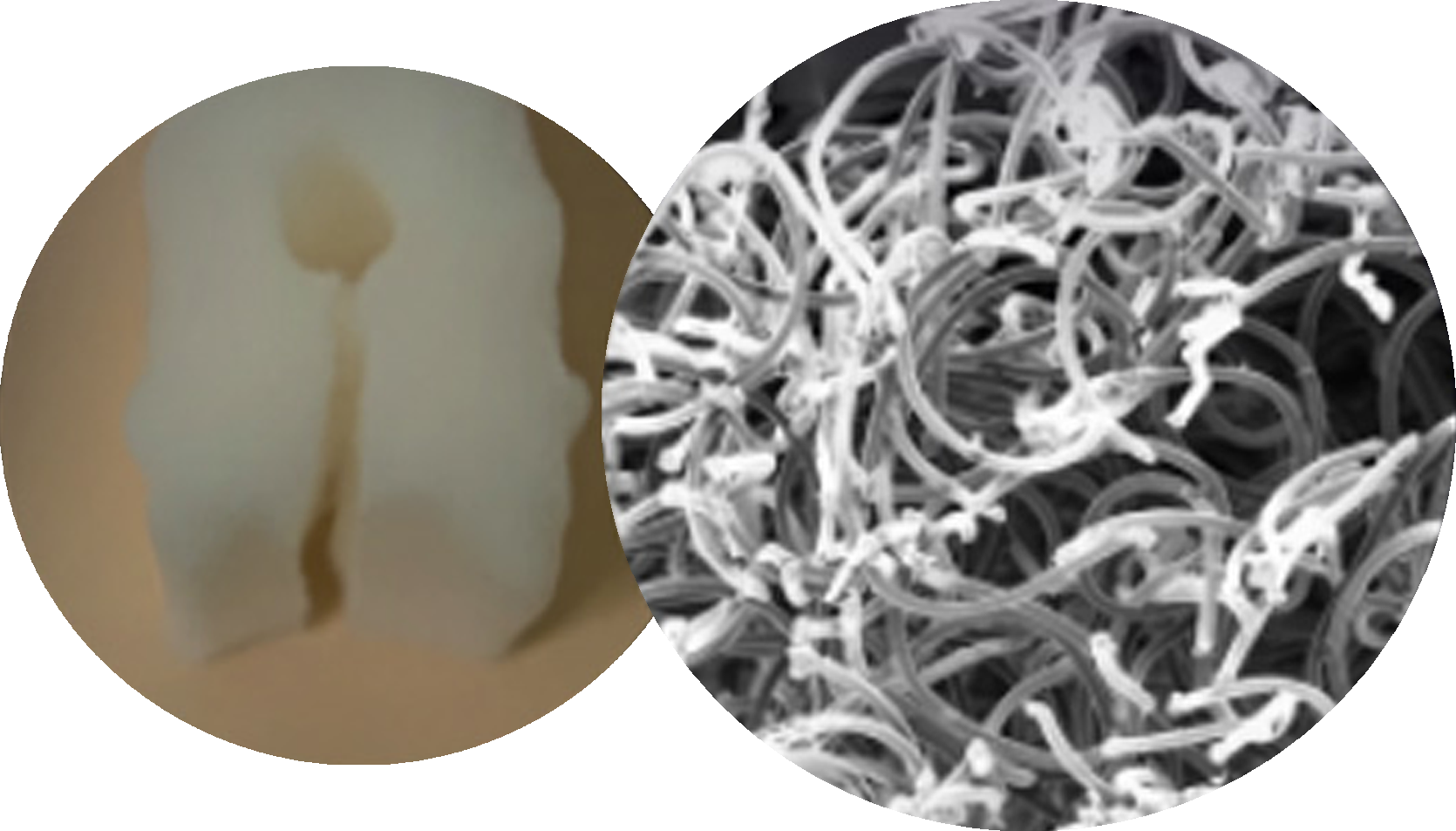

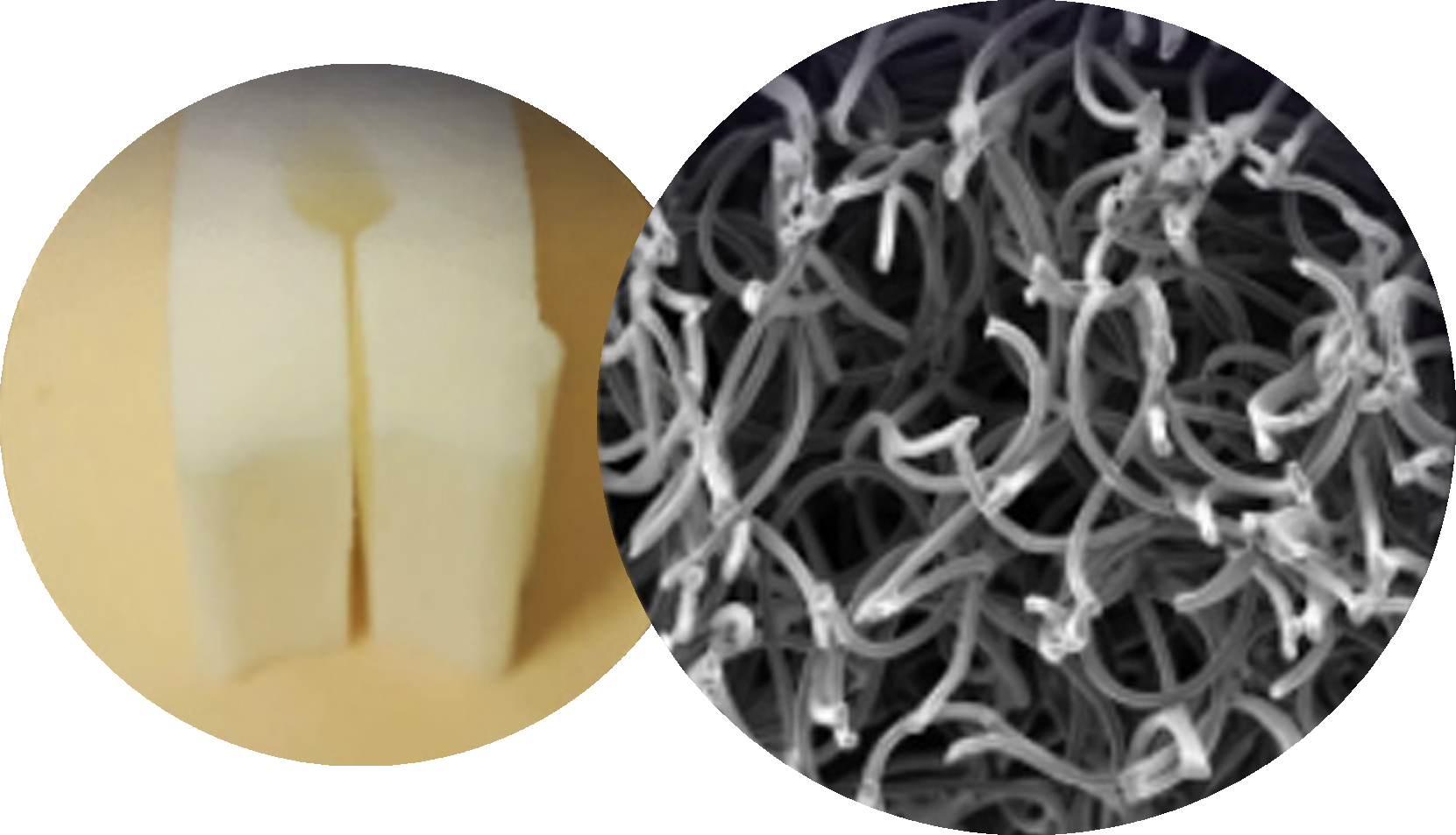

VPU NON-WOVEN STANDARD

The Industry-leading Testing Standard

Unqualified Non-woven

VPU-standard Qualified Non-woven

Our team has achieved a major breakthrough in the performance of the through-air bonded non-woven material, ensuring consistent performance in each product batch and guaranteeing consistent quality of our products.

GEEK CERAMIC

CORE

Through the careful selection of raw materials and the molding process, we are able to precisely manage the pore size in the range of 0.1 to 80 microns. This allows us to match the best pore size for each application scenario with an uniform pore structure.

Safety Performance

Our R&D team has performed a thorough aerosol analysis to find solutions for excessive condensation, and similar issues. We have now developed a more balanced atomization effect, greatly reducing the possibility of scorching and thus improving overall safety of use.

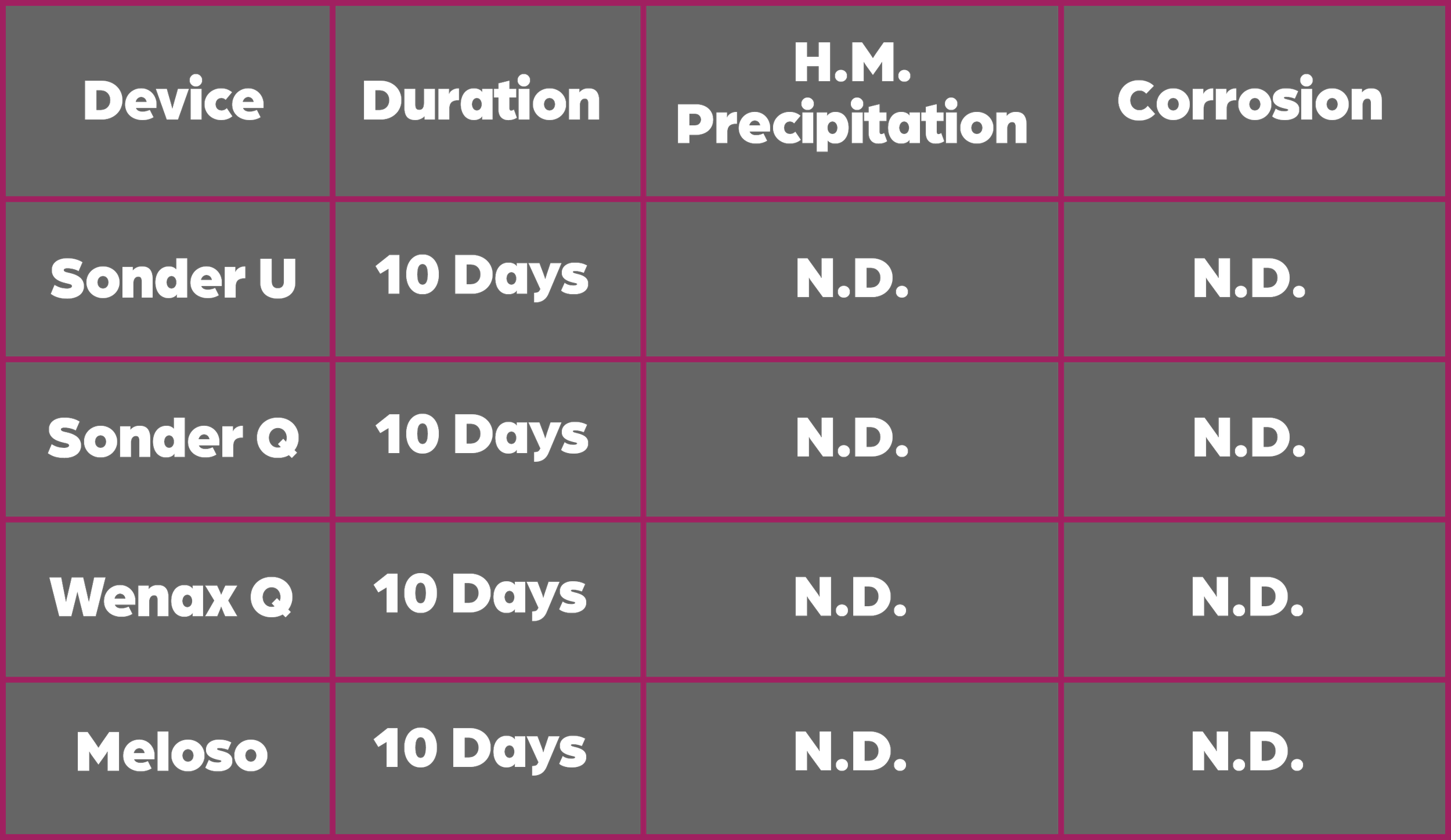

Results of the Precipitation of Heavy Metals & the Corrosion of Heating Coil

Our research found that when the heater was placed in liquid for 10 days during quality testing, the above products that used VPU technology did not show traces of heavy metals and corrosion of the heater.

UNIT PROCESS CONTROL

Statistics-based unit process control ensures consistency of quality from batch to batch, and GEEK's yield has increased to 99.5%.